Opteon™ & Vertrel™ Articles

Vapor Degreasing Solvents | Miller-Stephenson Solutions

Vapor Degreasing Solvents | Miller-Stephenson Solutions

Next-Generation Chemistry – Increased Cleaning Efficiency, Higher Worker Safety, Optimized Formulations

Miller-Stephenson has been at the forefront of the specialty cleaning fluid industry for over 40 years. Our highly specialized vapor degreasing solvents has provided manufacturers with the best balance of performance, worker safety and cost efficiency. As regulations continue to change the landscape of what solvents are available Miller-Stephenson is well prepared, with innovative new formulations to not only meet your current requirements but provide sustainable solutions as well. Today, it’s about making better choices that reflect the vision and values of your business, a commitment to quality, responsibility for worker safety, and a mission to help sustain the earth for future generations. It starts with intentionally developed chemistry that optimizes all of these values. For manufacturers who need a circuit board cleaner, electric motor degreaser, machined parts or other precision cleaner needs, performance is critical – but so is the safety of your workers. New regulations, more stringent requirements and sustainability initiatives give extra urgency to your selection when you want to replace trichloroethylene (TCE) or hydrochlorofluorocarbon (HCFC) solvents, find an n-propyl bromide (nPB) alternative, or avoid the pending hydrofluorocarbon (HFC) phasedown. Miller-Stephenson has engineered fluids ready to meet your solvent cleaning and vapor degreasing needs.

Replacing n-Propyl Bromide, TCE, and HCFC Vapor Degreasing Solvents

With significant toxicity concerns on the use of the vapor degreasing solvents n-propyl bromide (nPB) and trichloroethylene (TCE) and a global phase-out of ozone depleting substances like hydrochlorofluorocarbons (HCFCs), many engineers are seeking a safer, more sustainable alternative. We offer direct drop-in replacements for companies looking to move away from the tightly regulated n-propyl bromide solvents or interested in lowering their worker exposure and environmental impact. Whether you are looking for increased cleaning efficiency, lower cost, minimized global warming potential, or lower VOC, Miller-Stephenson has the technology and product stewartship to provide you an optimized solution. Miller-Stephenson solutions including the following:

Opteon™ SF-79 is a next-generation, high-performance specialty cleaning fluid designed to offer superior cleaning power, greater efficiency, and safety in an eco-friendly ultra low global warming potential (GWP) and non-ozone depleting formulation (ODP). Opteon™ SF-79 is chosen for vapor degreasing, because of its industry-leading solvency power (KB value), cost-effectiveness and safety.

Vertrel™ MCA is ideally suited for critical cleaning applications in modern, tight vapor degreasing equipment. It has “zero” ozone-depletion potential and a moderate global warming potential. A medium-strength precision cleaning fluid, widely used in many critical cleaning, drying, and high-value specialty uses where consistent and reliable cleaning performance is the paramount objective.

Vertrel™ SDG is designed to replace trichloroethylene (TCE) and n-propyl bromide (nPB) in applications where maximum cleaning power is needed. With high solvency, low surface tension and a high Kb value Vertrel SDG is an ideal high performance vapor degreasing solvent with excellent solvency power for a wide range of soils including oils, greases, waxes, hydraulic fluids, and silicone residues.

Vertrel™ SFR specialty fluid can solve your most difficult defluxing needs used in lead-free and no-clean solders. It has excellent solvency power for a wide range of soils including ionics. As a replacement for n-propyl bromide (nPB) in most circuit cleaning applications, Vertrel SFR Flux Remover is an excellent choice. It carries a moderate global warming potential and medium VOC content.

Vertrel™ SMT is engineered to provide unmatched performance in Defluxing, Precision metal Cleaning and removal of Rosin, Oils, and Ionic Contaminates. It is ideally suited for use in vapor degreasing equipment with solvency power for cleaning ionic soils and flux residues from electronic assemblies. Vertrel SMT has “zero” ozone-depletion potential, and low global warming potential and VOC.

Opteon™ SF-79 – Next-Generation Cleaning Chemistry; Superior Performance; Eco-friendly

Opteon™ SF-79 is next-generation, high performance specialty cleaning fluid designed to offer superior cleaning power, higher efficiency, and safety in a eco-friendly low global warming potential (GWP) and non-ozone depleting formulation. This cleaning fluid is easy to use and provides reliability without the hassles of acid testing or other maintenance common with nPB environments. Since it has no ozone depletion potential (ODP) and an ultra-low global warming potential (GWP) this is a long-term innovation for industrial cleaning applications. SF-79 was designed from its inception to be a direct nPB replacement, providing equivalent cleaning performance, cost-effectiveness, but with a drastically enhanced operator and environment friendliness. Ideally suited for vapor degreasing, precision cleaning of PCB boards, cold cleaning and removal of greases and oils. Opteon SF-79 is is superior replacement for n-propyl bromide and TCE across many demanding cleaning applications. Opteon™ SF-79 is increasingly chosen for vapor decreasing, because of its industry leading solvency power (KB value), as well as its improved safety and environmental properties. Benefits include:

- Superior cleaning performance (Kb value = 103)

- Excellent environmental profile: Low GWP (<15); No ODP

- 100% Non-Flammable

- Fast-Drying and low boiling point (47°C)

- Ideal replacement for nPB and TCE

Both the Vertrel™ and Opteon™ specialty fluids offer high efficiency, high solvency, and equivalent or superior performance to n-propyl bromide while forgoing the significant worker safety issues associated with n-propyl bromide and TCE. Here are five reasons it is an excellent replacement for nPB:

- Exposure Limit: Vertrel™ & Opteon™ fluids have extremely high exposure limits > 200 ppm. By comparison, Isopropyl alcohol (rubbing alcohol) has an exposure limit of 200 ppm. The exposure limit of nPB exposure limit is measured between 5 ppm – 10 ppm by varying standards organizations.

- Cleaning Performance: Vertrel & Opteon™ specialty fluids have the broadest range of cleaning power of any solvent family. KB values (a measure of cleaning power) range from 11 to a high of 110. Vertrel can match nPB’s cleaning power.

- Solvent Maintenance: Vertrel & Opteon™ fluids are inherently stable and do not need acid acceptance testing or stabilizer maintenance unlike nPB. In addition, the relatively high exposure limit of Vertrel enables the use of open top vapor degreasers, and solvent air monitoring can be kept to a minimum.

- Solvent Usage: Today’s cleaning equipment manufacturers have improved system design resulting in significant reductions in the amount of solvent emissions and reducing overall operating costs. Vertrel& Opteon™ are cost competitive with nPB as a result of the emissions reduction.

- Global Acceptance: These specialty fluids are globally accepted as a safe cleaning material. Many countries have classified nPB as a reproductive toxin. In Europe, nPB is labeled as R60 (may impair fertility); R63 (possible risk of harm to the unborn child); and R48/20 (harmful: danger of serious damage to health by prolonged exposure through inhalation).

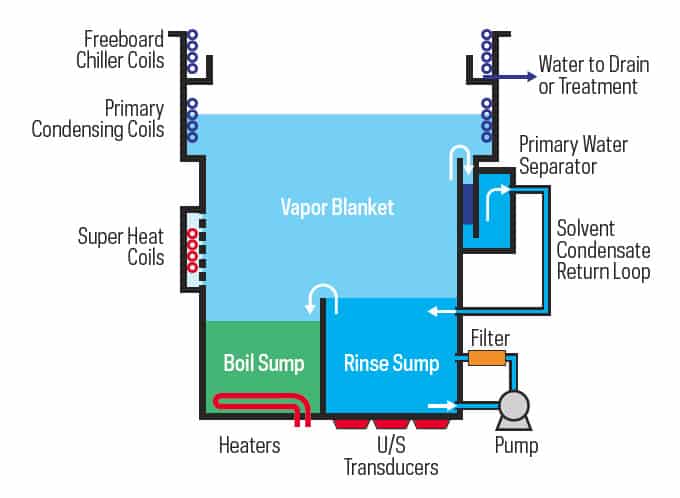

Vapor Degreasing Solvents – How Does A Vapor Degreaser work?

Vertrel specialty fluids have similar solvency strength as nPB. It is non-flammable, safe, and requires no stabilizers, making it an ideal replacement for nPB. Opteon™ products are also a great replacement for nPb.

Miller-Stephenson – 60 years of Technical Expertise…..at your service!

Miller-Stephenson is helping companies convert from nPB-based solvents to effective, safe and compliant alternatives. The goal of our support is that the replacement fluid will deliver cleaning results as good as or better than nPB at a similar cost-per-part-cleaned. Our support is designed to reduce the research and confusion of selecting a new chemistry, and ensuring a smooth and seamless transition. Miller-Stephenson can offer this commitment because we have a team of cleaning engineers, chemists and technical staff with dedicated to helping your transition, we offer on-site and off-site technical assistance. When the conversion begins, we launch our on-site technical support and a comprehensive product Stewardship Program. This program is designed to help each company lower cleaning costs, improve worker safety and protect the environment. The program educates workers about the cleaning products and processes, plus audits company procedures to ensure everyone works safely and profitably.

The recommendation made here with and the information set forth with respect to the performance or use of our products are believed, but not warranted to be accurate. The products discussed are sold without warranty, as to fitness or performance, express or implied and upon condition that purchasers shall make their own test to determine suitability of such products for their particular purposes. Likewise, statements concerning the possible uses of our products are not intended as recommendations to use our products in the infringement of any patent.