Krytox™ Lubricant Articles

Krytox™ Lube For Life

Krytox™ Electric Motor Lube For Life

A North American company improves equipment reliability by switching lubricants and joining the Lube for Life program.

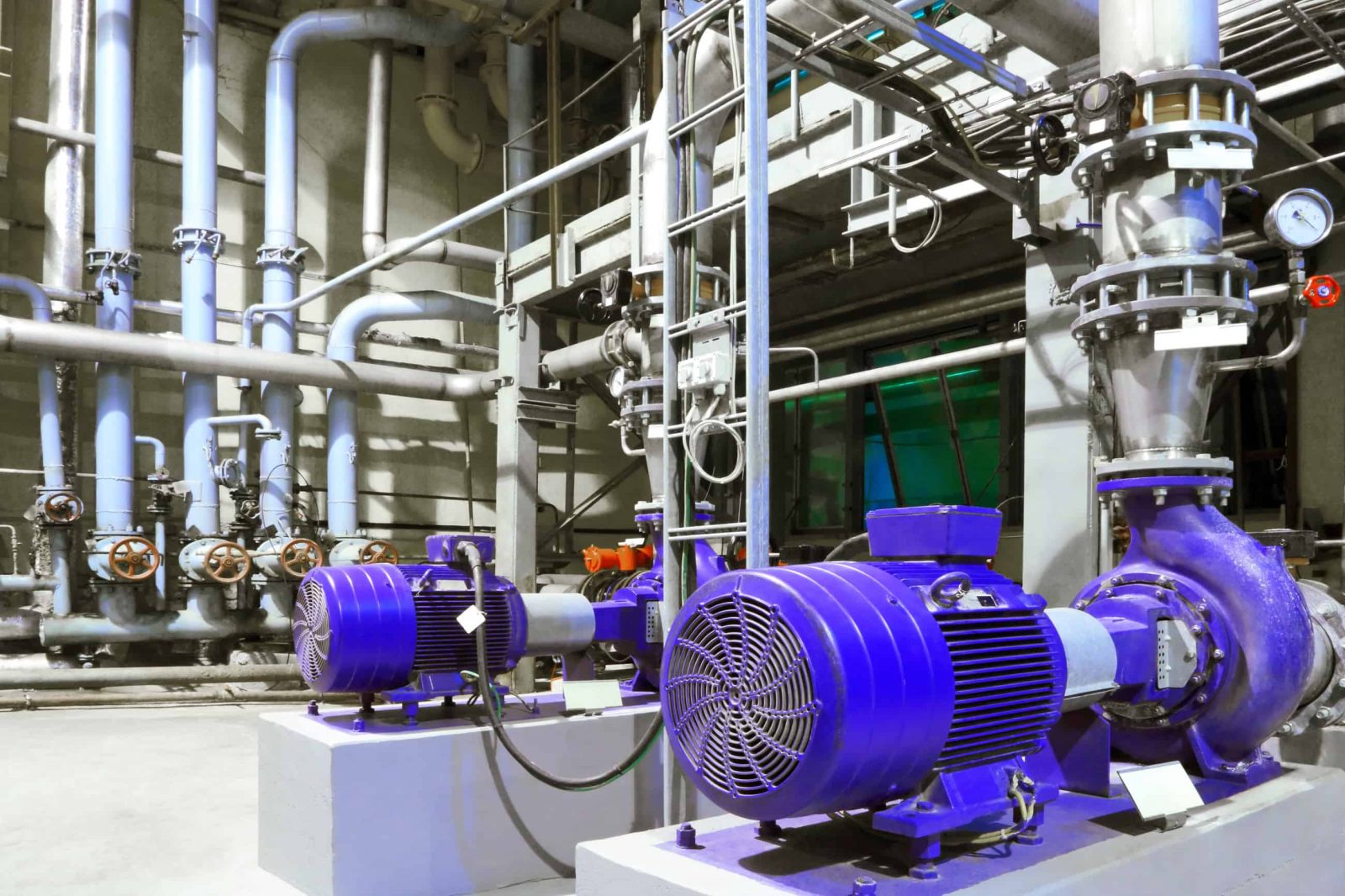

A major pulp and paper mill located in Western Canada wanted to improve the average operating life of its 3000 electric motor operating in a harsh environment without incurring additional costs for equipment or manpower.

The Challenge

For this application, the pulp and paper mill needed a ball bearing lubricant that could last the expected lifetime of their motors without the implementation of a cost prohibitive re-lubrication process. The mill’s reliability superintendent knew he could not afford to implement a system that relied upon ongoing re-greasing because of the additional equipment needed, unavoidable downtime and labor costs. However, he also realized that a more sophisticated greasing program was necessary to meet the increasing recommendations of industry experts and to avoid rebuilding and/or replacing failed motors.

The Solutions

After researching available options, the reliability superintendent turned to Krytox™ for help. Working with the Krytox™ technical service team, the mill implemented the use of Krytox™ grease AUT 2E45 on 100 motors as a pilot and the mill is now able to run its electric motors for their expected lifetime with no bearing failures attributed to lubrication. Switching to Krytox™ lubricants also avoided having to implement a re-lubrication process all together, saving significant manpower and downtime. The end result was a cost-effective, simplified process that not only met, but exceeded their expectations.

Key Advantages

- Using Krytox™ lubricant AUT 2E45, the pulp and paper mill was able to extend the service life of its electric motors and help ensure long-term reliability of the motor’s ball bearings.

- Krytox™ lubricant AUT 2E45 enabled the mill to avoid implementing a cost re-lubrication process.

- Krytox™ lubricants can be used in other electric motor applications to prevent oxidation and ensure no lubricant gum-up or breakdown for the lifetime of the motor. Excellent film-forming viscosity also enables the electric motors to spin with less resistant friction, leading to less maintenance and fewer bearing replacements.

Krytox™ greases offer the potential for lube for life lubrication in demanding electrical motor service. Krytox™ greases are non-oxidizing, water resistant, non-flammable and chemically inert.

Krytox™ greases contain perfluoropolyether (PFPE) oil and a polytetrafluoroethylene (PTFE) thickener. The PFPE oil and PTFE thickener will not oxidize and gum up like ordinary synthetic or hydrocarbon-based greases. Krytox™ greases are recommended by many major bearing manufacturers for long-life lubrication in severe applications. The superior film-forming capability of Krytox™ greases provide a thicker oil layer and reduce wear. Krytox™ greases are compatible with metals and most seal materials, but require removal of all old lubrications from the motor bearings before application. To learn more about Krytox™ Lube for Life greases please click this link.

Krytox™ is a trademark of The Chemours Company FC, LLC.

Recommended Products

Related Article Links

Krytox™ For Automotive Noise, Vibration, and Harshness

How to Prepare Bearings with Krytox™ Lubricants

The recommendation made here with and the information set forth with respect to the performance or use of our products are believed, but not warranted to be accurate. The products discussed are sold without warranty, as to fitness or performance, express or implied and upon condition that purchasers shall make their own test to determine suitability of such products for their particular purposes. Likewise, statements concerning the possible uses of our products are not intended as recommendations to use our products in the infringement of any patent.